Titanium plays a crucial role in industries such as aerospace, medical devices, marine equipment, and chemicals due to its exceptional strength, lightweight, and excellent corrosion resistance. Laser welding, as an advanced high-precision titanium joining process, is widely used due to its small heat-affected zone and high weld quality. Why is laser welding particularly suitable for titanium alloys?

Titanium alloys are strong, lightweight, and corrosion-resistant, but they are prone to oxidation and deformation during welding, thus requiring strict process control. Compared to traditional welding methods, laser welding offers superior heat input control, defect reduction, and weld quality, making it an ideal choice for titanium alloy welding.

Why are titanium alloys difficult to weld?

Why are titanium alloys difficult to weld?

High melting point (~1,668 °C): Requires a higher energy input than most metals.

Low thermal conductivity: Heat concentrates in the welding area, increasing the risk of localized overheating, deformation, and cracking.

Reactivity at high temperatures: Titanium readily reacts with oxygen and nitrogen to form brittle oxides, thus reducing weld integrity.

Limitations of Traditional Welding Methods

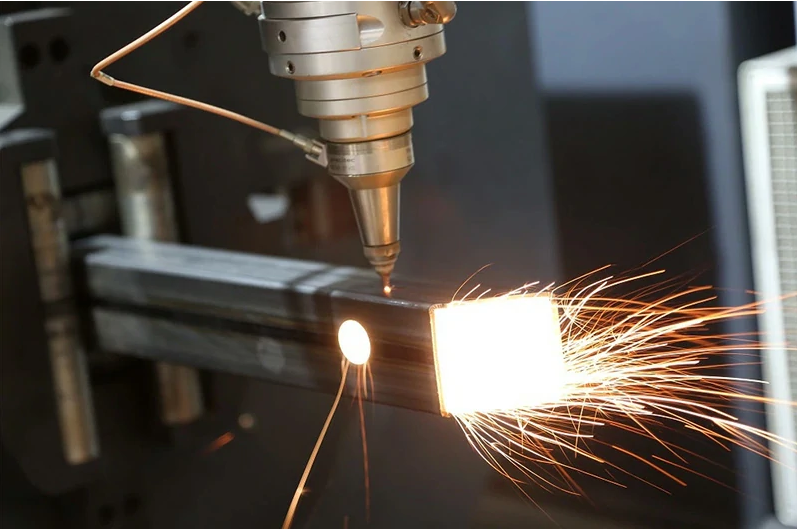

Traditional welding processes (such as TIG/MIG welding) often struggle to precisely control heat input and completely isolate the molten pool from air when welding titanium alloys. Improper operation can lead to defects such as oxidation, porosity, and cracking, which affect appearance and structural performance.

Common Problems in Titanium Welding

Oxidation/Discoloration: Blue/yellow hues indicate oxide formation and embrittlement due to insufficient shielding.

Deformation: Concentrated heat in thin sections can cause warping and dimensional loss.

Porosity: Moisture or contaminants can introduce porosity, reducing joint strength. Precision Welding and Fine Thermal Control

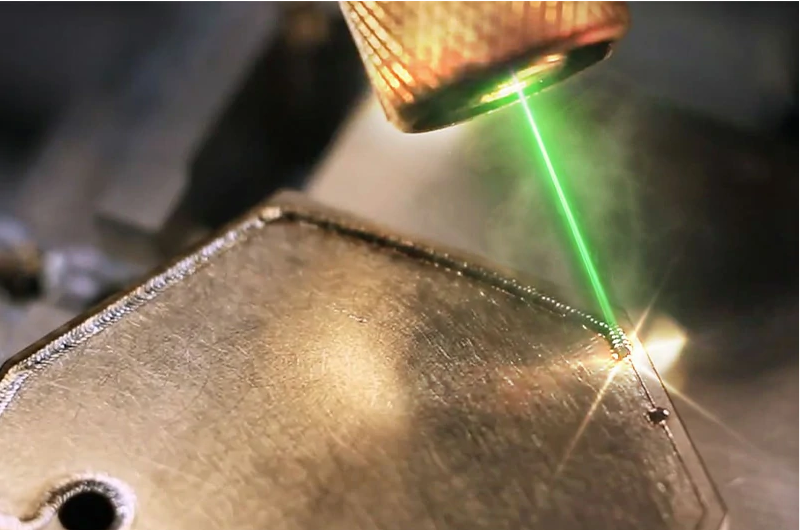

Laser beams can be highly focused for precise weld positioning—ideal for thin-walled parts, complex geometries, and small components. Controlled heat input prevents burn-through and misalignment, improving weld consistency. Laser welding concentrates heat, effectively reducing weld defects.

Laser weldin requires less total heat than conventional TIG welding.

Laser weldin requires less total heat than conventional TIG welding.

For materials like titanium alloys, less heat input means less likelihood of problems during welding. Properly controlling heat input can effectively reduce excessive oxidation of the weld, lower internal residual stress, and prevent excessive grain growth in the weld area, thereby improving weld quality and service life.

Welding thin-walled titanium alloys does not affect their strength.

Titanium alloys are widely used in thin-walled structures, especially in the aerospace and medical industries. Laser welding can achieve high-quality welds without reducing material strength. The weld strength is close to that of the base material, and post-weld properties remain stable.