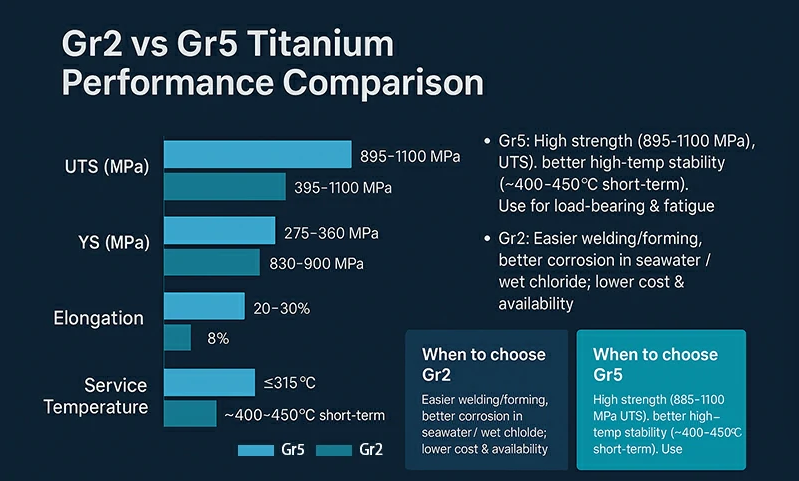

Need to quickly select the right titanium alloy grade for your seawater/chemical or aerospace/medical applications?

This page compares the composition, mechanical/thermal properties, corrosion resistance/weldability/imprintability of Grade 2 and Grade 5 titanium alloys, and provides ASTM/AMS standards, EN 10204 3.1 certification, available sizes, and a three-step material selection guide.

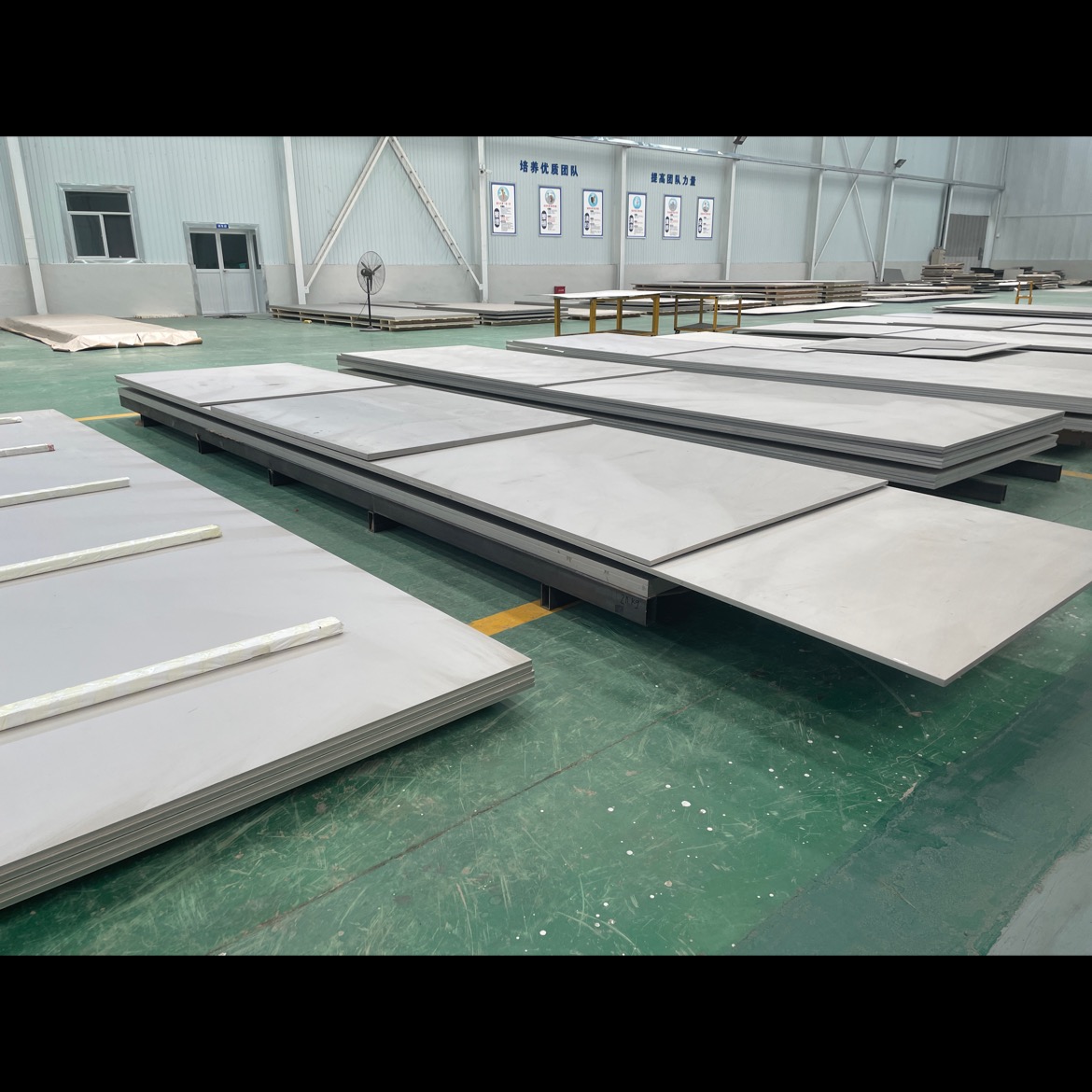

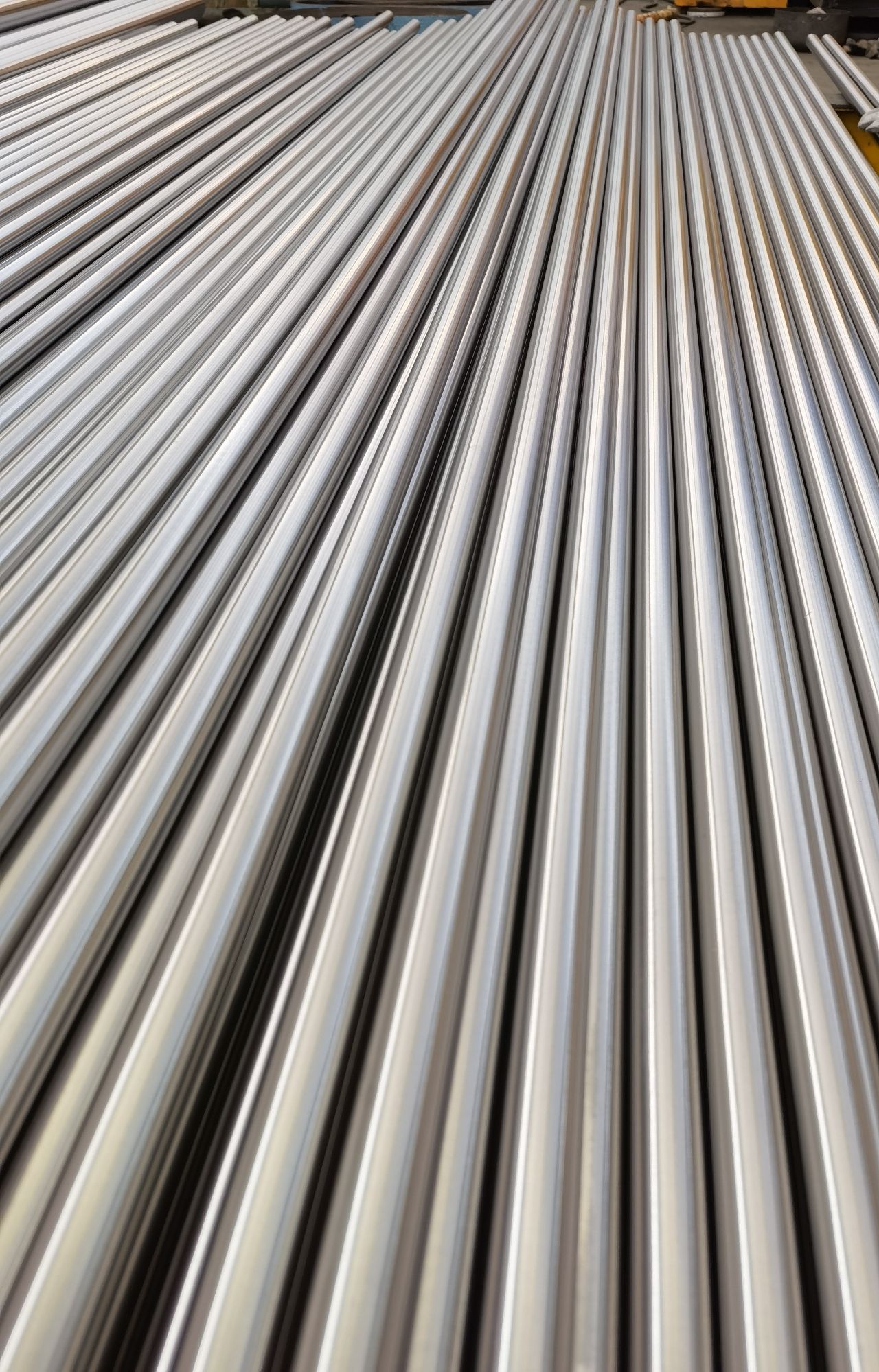

Quick Comparison in a Single Image: Grade 2 titanium alloy (CP Ti) is designed for seawater, chemical, flue gas depressurization, and other corrosion-resistant applications. Available in sheet, tube, bar, and forging forms, conforming to ASTM standards, with optional AWS/ISO welding documentation and third-party inspection reports. Supports fixed-length cutting, beveling/chamfering, and precision grinding. Adequate stock with complete batch traceability information.

Frequently Asked Questions: Is Grade 5 titanium alloy always better than Grade 2?

Not necessarily. If you require high strength, high temperature resistance, or high fatigue life, choose Grade 5; if you need to use it in seawater/wet chlorine environments and require better formability and weldability as well as lower cost, choose Grade 2. Can Grade 5 be used in seawater? Yes, but galvanic corrosion isolation and cost assessment are required. Level 2 is more stable and is the better choice for most seawater systems.

Is there a difference in welding difficulty? Yes. Level 2 has a wider welding window, while Level 5 welding requires strict control of heat input and shielding gas. Welding procedure specifications/weld quality records should be developed according to AWS D17.1/ISO 15614-5 standards.

Is the machinability stable and suitable for mass production?

Both titanium materials are prone to adhesive wear and work hardening; Level 5 is more sensitive. Low cutting speeds, high feed rates, shallow depths of cut, and adequate cooling should be used during machining. Precision grinding (TGP) and double-end machining of bars are recommended.

Which standards do you provide? What documents are included? We comply with ASTM B265 / ASTM B338 / ASTM B348 / ASTM B381 standards; Level 5 also supports AMS 4928 / 4911 standards. Delivery includes an EN 10204 3.1 certificate and inspection report (chemical composition, mechanical properties, dimensions, ultrasonic testing).

What are the delivery time and minimum order quantity (MOQ)? Standard sizes are in stock and can also be cut to order. Sample making for typical sizes takes approximately two weeks.

Minimum order quantity depends on size and processing requirements – please send us your requirements list for confirmation. What factors affect the price? Alloy grade, dimensions and condition (annealed/STA), processing services (hot pressing, shipping, machining), inspection level, and delivery urgency. How to choose the appropriate grade in three steps? Check the medium (strong corrosiveness → Gr2); check mechanical strength/temperature resistance (high strength/high temperature resistance → Gr5); confirm production feasibility and budget. Can you provide third-party inspection and traceability services? Yes. We support ultrasonic testing (ASTM B594), dimensional and surface roughness control, full batch traceability, and third-party witnessed inspection. Still unsure which grade to choose?