A sale is just the beginning; service has no end.

A sale is just the beginning; service has no end. I firmly believe that the best marketing is “no marketing,” and the best reputation is “your peace of mind.” Goodbye 2025, welcome 2026, and let’s continue to be your most reliable partner. We sincerely appreciate your continued support and cooperation over the […]

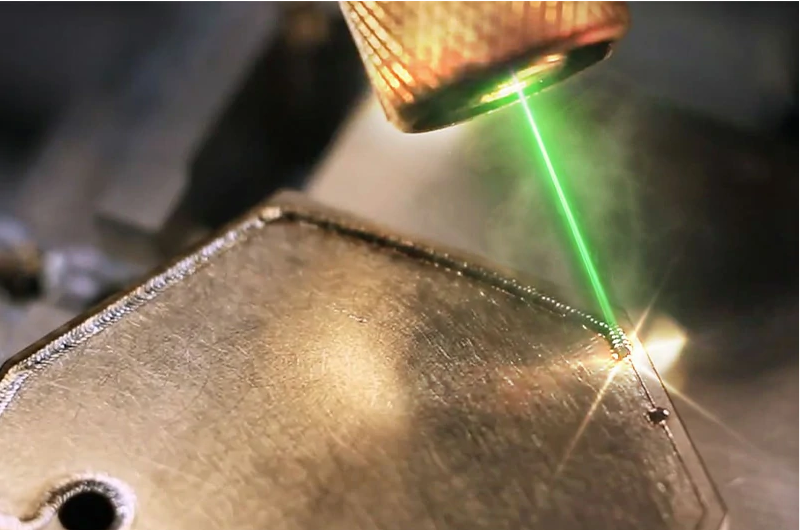

Laser welding of titanium

Titanium plays a crucial role in industries such as aerospace, medical devices, marine equipment, and chemicals due to its exceptional strength, lightweight, and excellent corrosion resistance. Laser welding, as an advanced high-precision titanium joining process, is widely used due to its small heat-affected zone and high weld quality. Why is laser welding particularly suitable for […]

Reminder: Place Your Orders in Advance for the Spring Festival Holiday

Reminder: Place Your Orders in Advance for the Spring Festival Holiday As the Chinese Spring Festival holiday approaches, our company will observe the official holiday schedule for the festival, with production, warehousing and logistics services to be suspended during this period. To ensure your orders are processed, produced and delivered on time without […]

Wishing you and your team a strong start to 2026.

Wishing you and your team a strong start to 2026. Hope we can achieve even better results together this year . Reflecting the last year 2025, I couldn’t help but thank everyone who was a part of it and who contributed to making it a good year. Thank you for your support, partnership, and […]

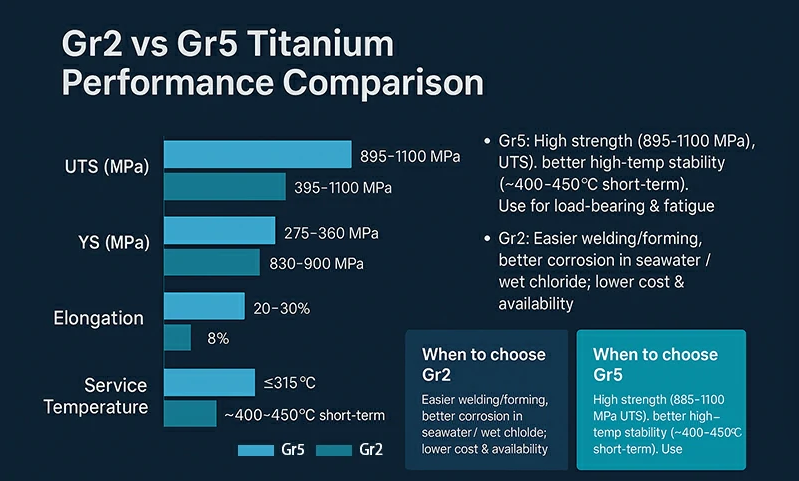

Gr2 titanium alloy and Gr5 titanium alloy

Need to quickly select the right titanium alloy grade for your seawater/chemical or aerospace/medical applications? This page compares the composition, mechanical/thermal properties, corrosion resistance/weldability/imprintability of Grade 2 and Grade 5 titanium alloys, and provides ASTM/AMS standards, EN 10204 3.1 certification, available sizes, and a three-step material selection guide. Quick Comparison in a Single Image: Grade […]

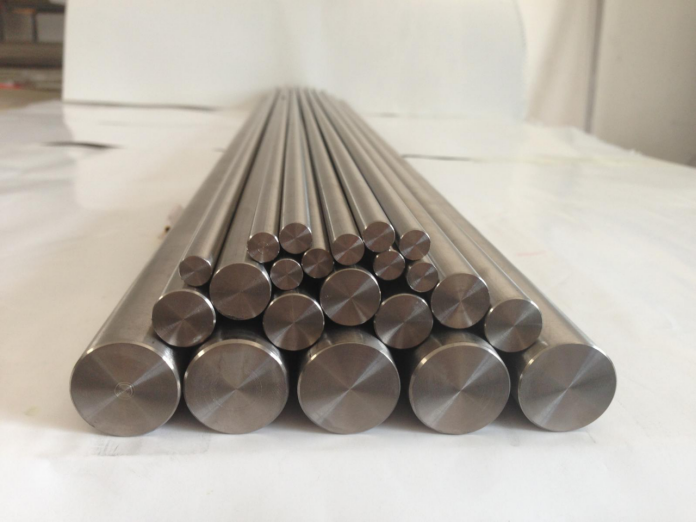

Titanium Wire & Bar → The Unsung Heroes of High-Performance Industries

Titanium Wire & Bar The Unsung Heroes of High-Performance Industries In an era where material science drives innovation, titanium stands out as a powerhouse metal. But today, let’s zoom in on two of its most versatile forms: <Titanium wire> and <Titanium bar> 1.Why Titanium? Titanium’s trifecta of properties—**high strength-to-weight ratio**, corrosion resistance, and bio […]

China Achieves New Breakthroughs in Critical Biomedical Materials Technologies

The Ministry of Industry and Information Technology and the National Medical Products Administration recently jointly released a list of innovative biomedical materials projects. Two titanium raw material projects from Baoji made the list, fully demonstrating the R&D and innovation capabilities of Baoji City—known as China’s Titanium Valley—in the field of biomedical materials. The Biomedical Materials […]

Heat Treatment of Titanium Rods :Unlocking the Key to Titanium Alloy Performance

Among numerous metallic materials, titanium alloys hold a pivotal position in various fields such as aerospace, medical devices, and automotive manufacturing due to their exceptional properties, including high strength, low density, and excellent corrosion resistance. As a key application form of titanium alloys, the quality of titanium rods directly impacts the performance and reliability of […]

Titanium Alloy Springs :The “Elastic Pioneers ”in High-End Applications

Precision deployment and retraction on aircraft landing gear, Gentle support for life-sustaining in medical device……Titanium alloy springs, with their unique performance advantages, are becoming indispensable key components in numerous high-end fields. This article will delve into the performance characteristics, manufacturing challenges, and solutions for titanium alloy springs, while showcasing their diverse application scenarios. I. Outstanding […]

Analysis of the causes of geometric accuracy deviations in titanium rods and related characteristics of hot forming

During the manufacturing process of titanium rods, geometric accuracy deviations are a common issue that requires close attention. A thorough investigation into the causes of geometric accuracy deviations in titanium rods is of great significance for improving the quality of titanium rod processing and optimizing processing techniques. Research has shown that geometric accuracy deviations in […]