Titanium alloy, as a high-performance metal material, has demonstrated broad application potential in many fields such as aerospace, medical care, sports, and chemical engineering due to its excellent mechanical properties, corrosion resistance, and lightweight characteristics. However, the properties of titanium alloys are not fixed. Their heat treatment state (annealed state, hot-worked state, cold-worked state) significantly affects the microstructure, physical properties, and machinability of the material. This article will analyze the characteristics of the three states in depth, providing scientific reference for actual procurement and engineering applications.

1. Annealed state (M): Stress relief, improved plasticity and toughness

Annealed state (M) titanium alloy undergoes high-temperature annealing treatment, which fully releases internal stress, homogenizes the microstructure, significantly improves the material’s plasticity and toughness, and simultaneously reduces hardness In this state, titanium alloys have the following characteristics:

Excellent machinability: Compared to the hot-worked condition (R), M-condition titanium alloys are easier to machine and stamp.

Controllable hardness range: Affected by annealing temperature and time, the hardness of M-state titanium alloy is usually between 32 and 38 HRC, which is suitable for applications that require moderate strength but also plasticity.

Application scenarios: Commonly used in structural parts that require good formability, such as thin-walled parts for aviation and pre-machined parts for medical implants.

2. Hot-worked condition (R): High strength but limited plasticity, requiring careful selection.

The hot-worked condition (R) refers to the state of titanium alloy after hot rolling or forging without heat treatment. At this point, the material retains residual stress from the processing, and has the following characteristics:

High strength, low plasticity: R-state titanium alloys have high strength but poor plasticity and ductility, which may be detrimental to subsequent processing or pose a risk of cracking.

Significant hardness fluctuations: Due to the influence of alloy composition and rolling process, there are significant differences in the hardness of R-state titanium alloys, which need to be evaluated according to specific requirements.

Application recommendation: Unless extremely high strength is required and no subsequent processing is necessary, it is generally not recommended to use R-state titanium alloy directly as the delivery condition.

3. Cold-worked condition (Y): High-strength hard condition, specifically designed for high-performance applications.

Cold-worked (Y) titanium alloy has not undergone annealing treatment, and the material is in a hard state, combining high strength with low plasticity:

Performance advantages: Cold-worked titanium alloys have significantly improved strength and hardness, but reduced plasticity and ductility, making them suitable for manufacturing high-load-bearing, wear-resistant components.

Typical application areas:

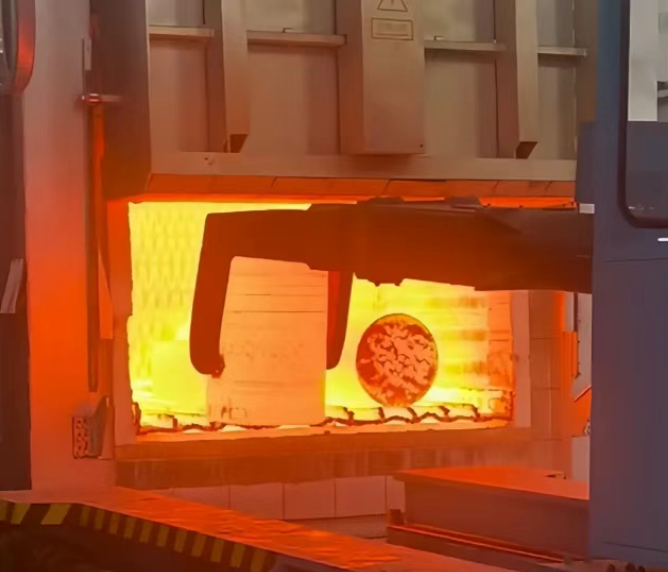

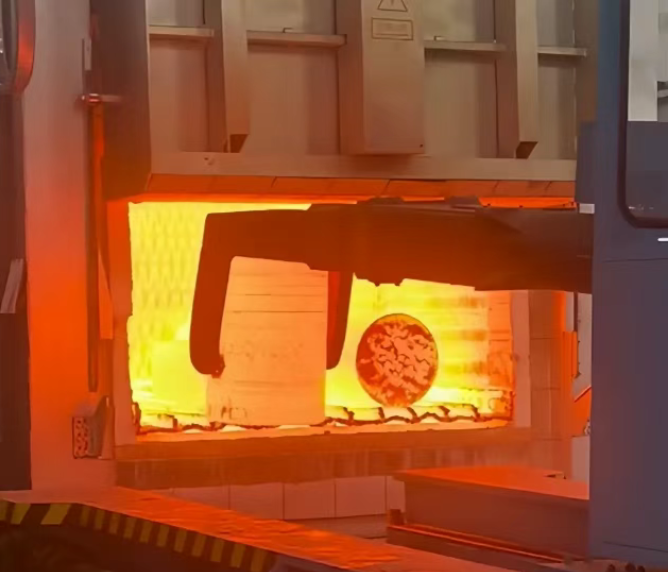

Aerospace: aircraft structural components, engine components (such as blades and shafts);

Marine engineering: pressure-resistant hulls, propellers;

Chemical equipment: corrosion-resistant pipes, reactors;

Medical devices: High-strength implants (such as orthopedic fixation devices)。

Key points for procurement: It is necessary to clarify whether the material requires subsequent heat treatment to avoid processing difficulties caused by excessive hardness.

4. Selection recommendations: Combine requirements and match preciselyIn actual procurement, users should select the heat treatment state of titanium alloys based on the following factors:

1) Processing requirements: If subsequent cutting and forming are required, annealed state (M) should be selected as the first choice;

2) Strength requirements: Cold-worked condition (Y) can be selected for high-strength applications, but the feasibility of processing must be assessed;

3)Cost and efficiency: Although the hot-worked state (R) has high strength, it may increase subsequent processing costs and risks, so careful consideration is required.

Scientific material selection empowers high-end manufacturing

The heat treatment state of titanium alloys is a core factor in controlling their performance. By understanding the differences in the characteristics of the annealed state (M), hot-worked state (R), and cold-worked state (Y), users can more accurately match materials to engineering requirements, achieving an optimal balance between performance, cost, and processing efficiency. Whether in aerospace, medical implants, or chemical equipment, scientific material selection remains a critical step in high-end manufacturing.