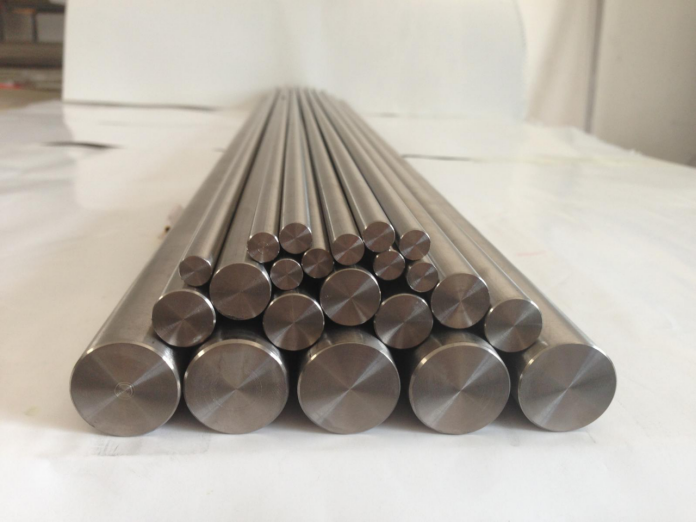

Among numerous metallic materials, titanium alloys hold a pivotal position in various fields such as aerospace, medical devices, and automotive manufacturing due to their exceptional properties, including high strength, low density, and excellent corrosion resistance. As a key application form of titanium alloys, the quality of titanium rods directly impacts the performance and reliability of related products. During titanium rod production, heat treatment serves as a magical key, precisely enhancing the material properties of titanium alloys to endow the rods with superior comprehensive characteristics.

Heat Treatment: The Shaper of Titanium Bar Properties

The core purpose of heat treatment in titanium rod production is to enhance the material properties of titanium alloys. During the processing of titanium alloys, internal stresses are generated. These stresses act like hidden “time bombs” within the material, potentially causing deformation, cracking, and other issues during the use of titanium rods. Heat treatment effectively eliminates these internal stresses, laying the foundation for the stable performance of titanium rods.

At the same time, heat treatment can also adjust the crystal structure of titanium alloys. The crystal structure acts as the material’s “skeleton,” and its rationality directly impacts the material’s mechanical properties, corrosion resistance, and other characteristics. Through heat treatment, the crystal structure can be optimized to achieve a more ideal balance in strength, hardness, toughness, and ductility. This significantly enhances the mechanical properties, corrosion resistance, and overall performance of titanium rods, meeting the diverse performance requirements across various fields.

Detailed Explanation of Heat Treatment Processes

Annealing: Stress relief and enhanced ductility

Annealing is the first step in the heat treatment process, akin to releasing tension from the titanium alloy. The specific procedure involves heating the titanium alloy to a precise temperature, which must be determined based on the alloy’s composition and application requirements. Once heated to the target temperature, the alloy is allowed to cool slowly. During this process, internal stresses are gradually released, much like a tightly coiled spring slowly returning to its original state.

The benefits of annealing are substantial. It enhances the plasticity of titanium rods, making them more amenable to subsequent machining operations. Simultaneously, the improved crystalline structure boosts the rods’ toughness and ductility. This enables the titanium rods to better absorb energy when subjected to external forces without fracturing, significantly enhancing their reliability and service life.

Aging Heat Treatment: Stabilizing Performance, Enhancing Characteristics

After undergoing annealing treatment, the titanium alloy proceeds to the aging process. Aging involves holding the annealed titanium alloy at a specific temperature for a designated period—both the temperature and duration are meticulously designed and experimentally validated.

Under the influence of this specific temperature, the crystal structure of the titanium alloy undergoes further refinement and optimization. Much like meticulously carved jade, the strength and hardness of the titanium alloy are significantly enhanced after aging treatment, resulting in more stable performance. Whether subjected to high temperatures, high pressures, or complex corrosive environments, aged titanium rods maintain outstanding performance, providing robust assurance for the long-term stable operation of products.

Solution Treatment: Elemental Fusion, Structural Optimization

For certain specific compositions of titanium alloys, solution treatment is an essential process. Solution treatment involves uniformly dissolving alloying elements into the titanium matrix at high temperatures. The high temperature acts like a “melting furnace,” allowing various elements to mix thoroughly and form a homogeneous solid solution.

Subsequently, rapid cooling “locks” the distribution of alloying elements within the titanium matrix, thereby adjusting the alloy’s crystalline structure and strength. Through solution treatment, the internal microstructure of titanium alloys becomes more uniform and their properties more stable, providing a more reliable material foundation for titanium rod applications under diverse operating conditions.

Quenching: Solution treatment for shaping and strengthening properties

In certain cases, titanium alloys require rapid cooling after solution treatment, a process known as quenching. Quenching acts like setting the shape of the titanium alloy. By cooling it quickly, the solid solution state is preserved, preventing alloying elements from precipitating during cooling and forming structures detrimental to performance.

Quenching achieves higher strength and hardness, enabling titanium rods to maintain stable shape and performance even under heavy loads and complex stresses. For instance, in aerospace applications where material strength and hardness demands are extremely high, quenched titanium rods meet the operational requirements for aircraft under extreme conditions such as high-speed flight and complex aerodynamic loads.

Precision Control: The Art of Heat Treatment Parameters

The parameters of heat treatment processes—such as temperature, time, and rate—are not fixed but require flexible adjustment based on the specific composition of the titanium alloy, application requirements, and the manufacturer’s experience. Different titanium alloy compositions exhibit distinct crystal structures and performance characteristics, necessitating tailored heat treatment parameters to unlock their optimal properties.

Application requirements also significantly influence heat treatment parameters. For instance, when titanium rods are used in aerospace components demanding exceptional strength and corrosion resistance, heat treatment parameters should prioritize enhancing these properties. Conversely, for medical devices requiring high biocompatibility and toughness, parameter adjustments will correspondingly emphasize these aspects.

The experience of manufacturers is equally significant. Companies with extensive experience in titanium alloy processing have accumulated rich heat treatment expertise through practical application. They can promptly adjust heat treatment parameters based on varying production conditions and product quality feedback, ensuring the stable performance and reliable quality of the produced titanium rods.

Proper heat treatment processes are crucial for enhancing the performance of titanium rods. Through the judicious application of heat treatment steps—including annealing, aging treatment, solution treatment, and quenching—and precise control of heat treatment parameters, titanium rods can be tailored to meet diverse application requirements, enabling them to perform more effectively across various fields. As technology advances and demands for material performance continue to rise, heat treatment processes will undergo continuous innovation and refinement. This evolution will inject new vitality into the titanium alloy industry, driving the widespread adoption of titanium rods in more high-end applications.