Through extensive testing and practical application, titanium tubes have been proven to offer significant advantages over other materials in power plant condensers, both technically and economically. From an economic perspective, taking a 1,000 MW condenser nuclear power plant in Japan in 1983 as an example, the plant required approximately 50,000 condenser tubes, and the condenser was designed to have a service life of 40 years. During this period, the average annual leakage rate for aluminum-copper pipes was 10 pipes, while titanium pipes had almost no leakage over a 40-year period. However, the practical application of titanium alloy tubes in power stations has not been smooth sailing, and there are still some issues that need to be addressed, specifically as follows:

corrosion issues

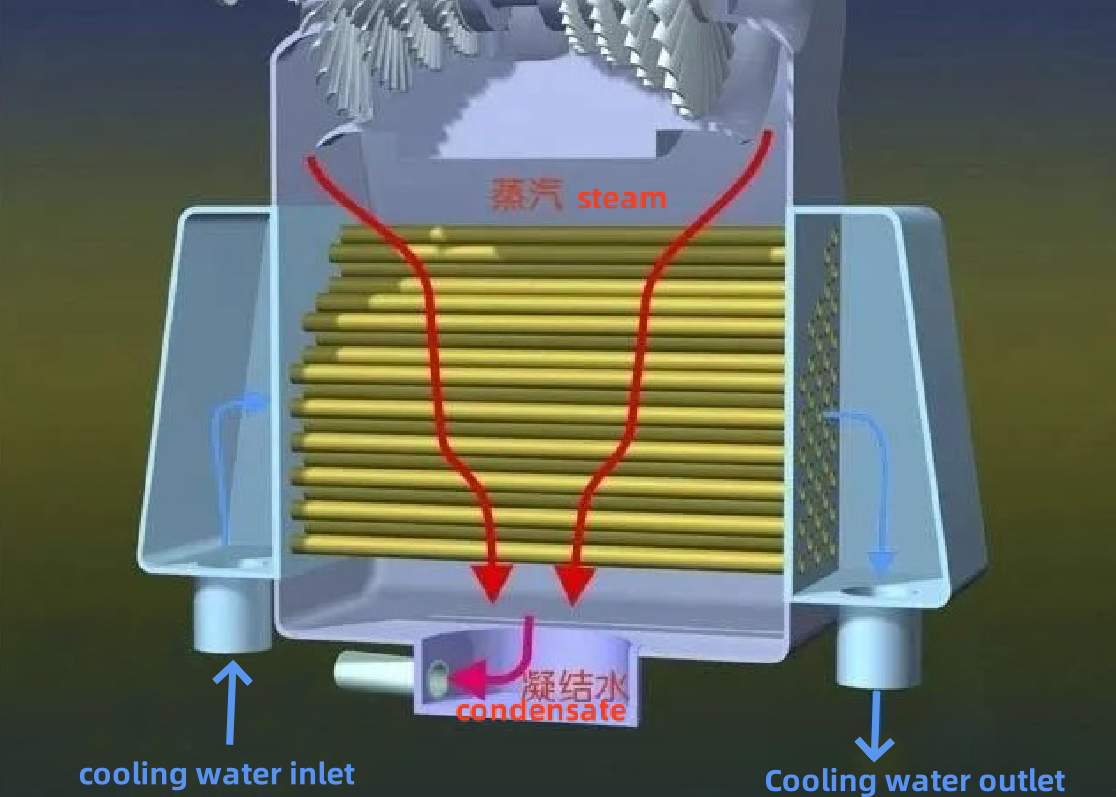

In coastal power plants, seawater is often used as cooling water for condensers. Seawater is rich in mud, suspended solids, marine organisms, and various corrosive substances. In a slightly salty water environment where seawater and river water alternate, the situation is even more complex and severe.Traditional copper alloy pipes are subject to various types of corrosion in such harsh environments, including general corrosion (uniform corrosion), erosion, and stress corrosion.

Titanium alloy tubes, with their excellent corrosion resistance, effectively prevent seawater leakage accidents caused by condenser corrosion. However, it is worth noting that unlike copper alloy pipes, titanium alloy pipes, although corrosion-resistant, are prone to the growth of toxic substances on their surfaces, which provides a “breeding ground” for marine organisms to attach themselves. The large accumulation of marine organisms on the inner walls of titanium tubes can severely impair heat transfer efficiency, thereby reducing the operational efficiency of the condenser. Therefore, when using titanium alloy tubes in power plants, it is essential to install appropriate cleaning equipment to regularly remove marine organisms adhering to the inner walls.

Hydrogen inhalation issues

Although titanium surfaces form a dense passivation film that gives them excellent corrosion resistance in many strong corrosive media, titanium has a high affinity for hydrogen and readily absorbs hydrogen gas.This hydrogen absorption phenomenon occurs at room temperature, and the hydrogen absorption rate increases significantly at high temperatures (such as 100°C). The solid solubility limit of hydrogen in titanium is extremely low, approximately 20 ppm. Once this limit is exceeded, hydrogen compounds (TiH₂) precipitate on the titanium surface. As the hydrogen content on the titanium surface increases, the impact value and elongation of titanium decrease rapidly, seriously affecting the mechanical properties and service life of titanium tubes.

In addition, during the renovation of old units, if copper alloy is used for the tube sheet and titanium is used for the condenser tubes, a cathodic protection device must also be used to prevent electrochemical corrosion.For example, Hitachi power plant condensers use seawater cooling, with titanium tubes and copper alloy plates used in combination. When the protective potential is lower than 0.75V (SCE), hydrogen absorption occurs at the outlet end of the titanium tubes, and after one year of use, the hydrogen content can reach 650ppm. However, when the potential is controlled within the range of 0.5–0.75 V (SCE), titanium does not absorb hydrogen at room temperature.

vibration issues

The excellent corrosion resistance of titanium tubes ensures that titanium condensers will not be damaged by corrosion leaks, but vibration poses another major threat to the safety of titanium tubes. In actual operation at power stations, titanium tubes may be damaged due to vibration.To avoid titanium tube vibration issues, it is necessary to accurately determine the appropriate baffle spacing when manufacturing titanium condensers in order to effectively suppress titanium tube vibration.For old unit renovation projects, it is even more important to carefully examine whether the original partition spacing is suitable for the use requirements of titanium tubes. Adjustments should be made when necessary to ensure the stability and safety of titanium tubes during operation.

n summary, although titanium alloy tubes have many advantages in the application of power station condensers, issues such as corrosion, hydrogen absorption, and vibration still require serious attentio. Only by fully recognizing and addressing these issues can we better leverage the advantages of titanium alloy tubes and improve the operational efficiency and safety of power plants.